For a long time, HDPE pipes have been widely used in the construction and transformation of water supply and drainage pipes in trenchless technology because of their excellent flexibility and corrosion resistance. However, while HDPE pipes have obvious advantages, there is also a serious problem: the pipeline is easy to scratch the surface when entering the old pipe or perforation, resulting in additional stress at the damage site, and there is a dangerous situation of crack expansion during the use of the pipe. Removing debris and sediment from old pipes is often difficult to achieve good results, so it is necessary to protect HDPE pipe surfaces from damage.

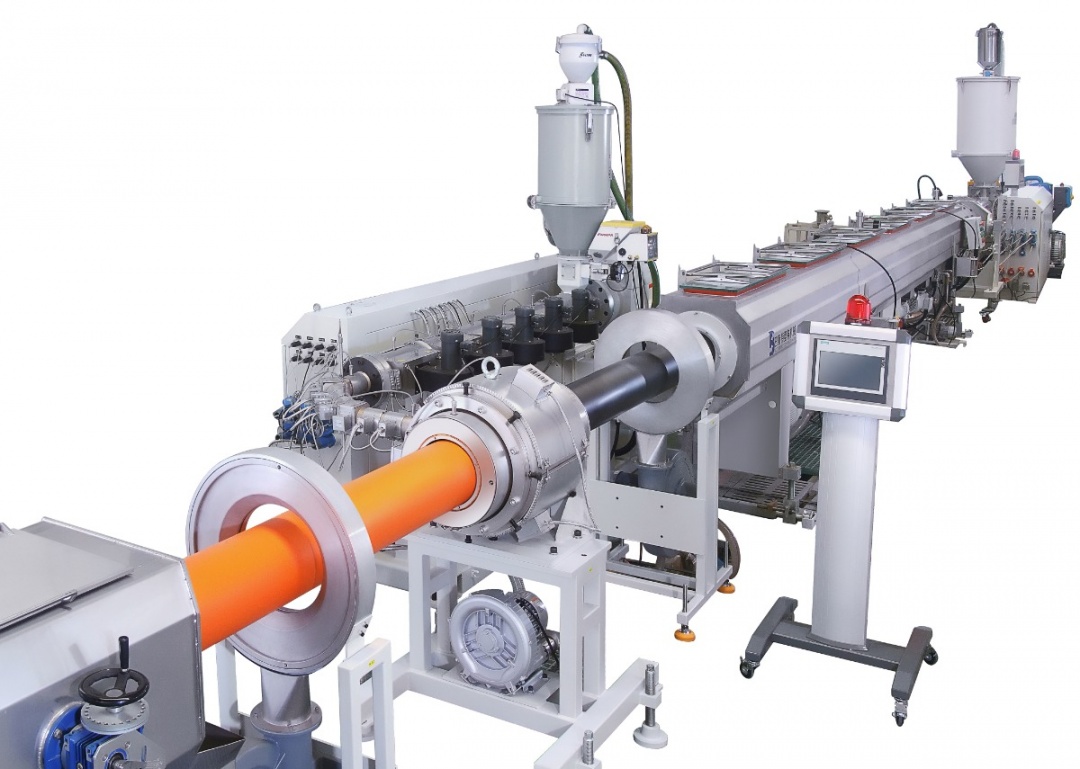

The outsourced laminating equipment is a special pipe mold designed by Guangdong BAST for excavation-free HDPE pipe. In the standard HDPE pipeline, a layer of high-hardness scratch protection layer is covered to avoid the damage to the surface of the pipeline during transportation and construction, reduce the impact of mechanical damage on the life of the pipeline, and greatly reduce the cost of transportation and installation. Even under harsh construction conditions, it will not cause damage to the pressure layer, and the original ordinary HDPE pipeline production line can be upgraded.

HDPE pipe outer cladding layer generally uses a harder material (such as MPP), the thickness is generally 0.9mm to 5mm, and increases with the increase of pipe diameter (see foreign standards in the annex); The outer cladding layer can be peeled off to facilitate the welding of HDPE pipes.

Why choose us

GUANGDONG BAST EXTRUTECH CO., LTD. was established in 2008, is committed to the research and development and innovation of high-end plastic machinery and equipment. The company for customers in all regions of the world, the business scope covers pipe extrusion equipment, coating & casting equipment, heavy bags / cold drawing / heat shrinking film blowing equipment three major business segments, is a set of technology research and development, production and assembly, sales and service as one of the equipment suppliers.

Looking at the world, BAST's equipment has always been known for its stable products, superior performance, high efficiency and energy saving, and has achieved digital, diversified and international upgrading and development in the field of plastic equipment. With a strong business lineup and technical team, BAST through continuous innovation and practice to lead the industry energy-saving and high-quality development, the company independent research and development applications and authorization of as many as 32 patents, equipment energy consumption, efficiency and stability are among the best, the application of related patented technology equipment performance reached the leading level in the same industry.

Rigorous design, strict standardized manufacturing process, timely parts protection, customer-oriented after-sales service concept, has created BAST excellent performance of machinery and equipment and high-quality and intimate service products. In the future, BAST will help more enterprises accelerate scientific and technological innovation and upgrading and transformation, and jointly achieve the coordinated development of the industry!

Promote industry progress and become the world's BAST

Add: No. 1, Zhanxiang Road, Fengxiang Industry park, Daliang, Shunde, Foshan, Guangdong, China

P.C.: 528300

Tel:0757-23660568

Fax: 0757-23660578

E-mail: admin@bestextrusion.com

Website:m.jungrew.cn