With the development of social economy and the continuous changes in consumption patterns, users have increasingly high requirements for the functionality of film use. The packaging industry is increasingly in need of various types of high functionality and specialized packaging, and single-layer film packaging can no longer meet the increasing needs of the market's packaging level.

Economy, versatility, and high strength are the development trends of the packaging industry, and multi-layer co extrusion coating technology provides good technical support for them. The multi-layer co extrusion method, as a one-time film processing method, avoids traditional post processing processes such as composite and coating, and can effectively reduce production costs. At the same time, the use of multi-layer co extrusion method can combine various polymers with different characteristics in different structures during the extrusion process, giving the film different excellent properties, such as heat sealing, barrier, damage resistance, chemical resistance, stiffness, hardness, etc. In food It has been widely used in fields such as medicine and packaging bags.

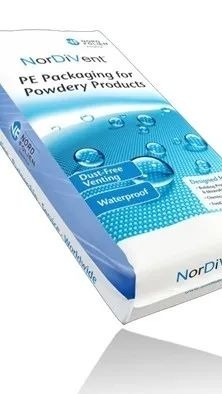

Among them, multi-layer co-extrusion heavy bag technology refers to the process of using three or more extruders to melt and extrude various resin raw materials with different functions, such as mPE, HDPE, LDPE, LLDPE, etc., and then composite co extrusion is carried out through a multi channel die. After cooling, shaping, and winding, the final heavy packaging bag with multi-layer structure and comprehensive performance is obtained. Heavy packaging bags can be widely used in raw material bags, rice bags, feed bags, and other fields, with good development prospects.

800 Five-Layer Ffs Line is a film forming vertical line equipment developed by GUANGDONG BAST EXTRUTECH CO., LTD, using multi-layer co extrusion technology. Compared with similar equipment, it has advantages such as high output, good product plasticity, and low energy consumption. The produced finished film has a thicker core layer and thinner surface layer, as well as a sub surface layer that can introduce specific functions in different layers, increasing the adjustability of the equipment and the diversity of the product through the excess number of layers. On this basis, innovative technology has significantly increased the overall output of equipment and the space for enterprises to improve efficiency and reduce costs, which is more in line with the high-speed development needs of the film industry.

Technical parameters of the 800 Five-Layer Ffs Line:

GUANGDONG BAST EXTRUTECH CO., LTD was established in 2008 and is committed to the research and innovation of high-end plastic machinery and equipment. The company faces customers from various regions around the world, with a business scope covering three major business segments: pipe extrusion equipment, coating&casting equipment, and heavy bag/cold stretching/heat shrink film blowing equipment. It is an equipment supplier that integrates technology research and development, production assembly, and sales services.

Looking globally, BAST's equipment has always been known for its stable products, superior performance, and efficient energy conservation. It has achieved digital, diversified, and international upgrading and development in the field of plastic equipment. With a strong business lineup and technical team, BAST leads the industry in energy-saving and high-quality development through continuous innovation and practice. The company has independently researched, developed, applied for, and authorized up to 32 patents, and the equipment's energy consumption, efficiency, and stability are among the top. The performance of the equipment applying related patent technologies has reached a leading level in the industry.

The rigorous design, strict standardized production and manufacturing process, timely accessory guarantee, and customer-centered after-sales service concept have created BAST's excellent mechanical equipment and high-quality and thoughtful service products. In the future, BAST will assist more enterprises in accelerating technological innovation, upgrading and transformation, and jointly achieve coordinated industrial development!

Promote industry progress and become the world's BAST

Add: No. 1, Zhanxiang Road, Fengxiang Industry park, Daliang, Shunde, Foshan, Guangdong, China

P.C.: 528300

Tel:0757-23660568

Fax: 0757-23660578

E-mail: admin@bestextrusion.com

Website:m.jungrew.cn